Radonova has always strived to scrupulously respect the regulatory requirements of all the countries in which we carry out radon measurements to ensure our customers receive a high quality of service. We meticulously take care to maintain our ISO17025 accreditation, participate in inter-comparative tests, while methodically following the measurement protocols defined by various national authorities. At the same time, we impose rigorous and particularly demanding quality control protocols internally to guarantee the best possible continuity and quality of our products.

Selection of raw material

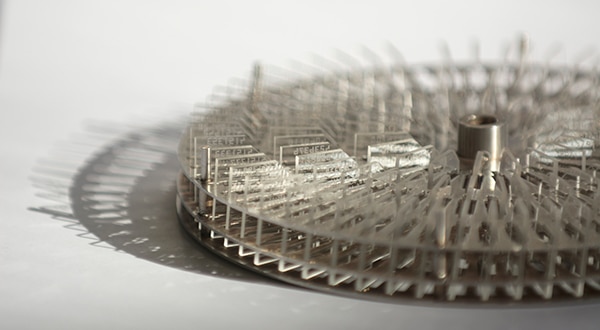

Radonova has several suppliers of CR39 plastic, so as not to risk any failure from one of the providers we are working with. This raw material is delivered to us in the form of batches from which we produce around 120 films ready to be introduced into our detectors.

After a first pre-etching step to clean the films, a smaller part of them are set aside to be tested. We place them under the microscope to count the number of alpha tracks already present on the film. The objective is to control the quality of the raw material supplied. The number of tracks measured must be below a certain value so that the films from the same batch can be placed on the assembly line.

Detector calibration

Once manufactured, 3% of the detectors are used for calibration exposures, which is a high value compared to some laboratories where 1% is the norm. This is one of the reasons why Radonova has industry leading quality in radon measurement. These detectors are sent to different national radiation chambers (PhE in England, BfS in Germany, SSM in Sweden and Bowser-Morner in the United States) where the calibration is performed. They are exposed to different radon levels in order to determine calibration factors representative of the typical values to which most detectors sent to our customers are exposed, but also to more extreme values in order to guarantee the effectiveness of the detectors in all situations.

The calibration factors used to determine the exposure of the detectors are calculated for batches of approximately 1000 to 2000 films.

Detector background calculation

Radonova also devotes a part of its production, 6% of the detectors, to calculate the unexposed background of the detectors. We basically calculate the average number of tracks which will have to be subtracted from the total number of tracks counted after the measurement. To do this, we etch and measure the films from the selected background detectors, just before the customer detectors are expected to be returned for analysis. In this way, we determine a proper background value for each batch of 120 films.

The typical background of a Radtrak2 detector is around 15 kBqh / m3 and the standard error of uncertainty is around 4 kBqh / m3.

In total, 12% of the CR-39 film produced and almost 10% of all detectors manufactured by Radonova will never arrive in our customers’ mailboxes. This requirement that we impose on ourselves and which, alongside the various national requirements in this area, allows us to maintain a very high level of quality for our customers and enables us to maintain our position as the global leader in radon measurement.